Plastic Injection Tooling Services in Texas

When it comes to building new tools that can meet your precise needs, T&R Tooling has you covered.

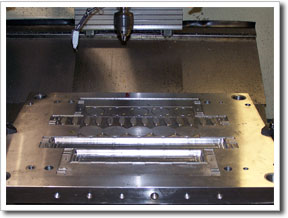

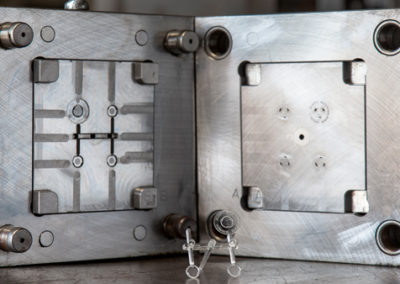

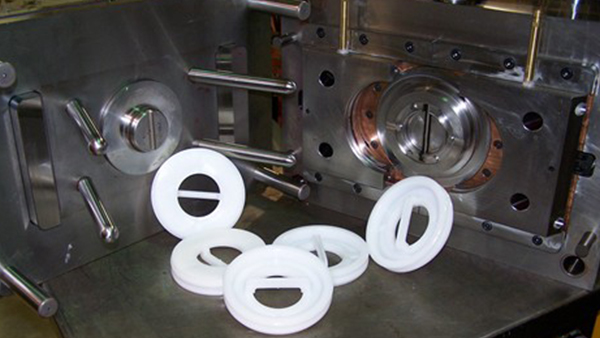

Using state of the art equipment, the professional team at T&R plastic injection tooling can build anything from single-cavity prototypes to multi-cavity hot runners. We are capable of constructing anything from class 101 to 105 tooling (see our “Mold Classification Table”) as well as providing a variety of solutions for budget conscious needs.

Contact T&R Tooling anytime to discuss our capabilities and how we can assist with your projects that require new tooling services.

T&R Tooling Mold Classification Table

| Mold Class | Usage Description |

| Class 101 | Extremely high volume production injection molds built for lifetime cycles exceeding one million. |

| Class 102 | Medium to high volume production injection molds built for lifetime cycles not to exceed one million. |

| Class 103 | Medium volume production injection molds built for lifetime cycles not to exceed 500,000. |

| Class 104 | Low volume production injection molds built for lifetime cycles not to exceed 100,000. |

| Class 105 | Prototype only and are molds built for lifetime cycles not to exceed 500. |

| Mold Classification Category | #101 | #102 | #103 | #104 | #105 |

| Stainless Steel Mold Base | X | ||||

| Stainless Steel Water Passage Mold Base Plates | X | ||||

| Total Runnerless Design (assumes part compatibility) | X | X | |||

| Spare Parts (quoted as a separate line item) | X | X | |||

| Automatic Molding Cycle & Automatic Part De-Gating | X | X | X | ||

| Full Detailed Mold Design | X | X | X | ||

| Heat Treated Cavity & Core Inserts | X | X | X | ||

| Parting Line Interlocks | X | X | X | ||

| Guided Ejection | X | X | X | ||

| Wear Plates on all Slides | X | X | X | ||

| Automatic Side Actions | X | X | X | X | |

| Cycle Counter (excludes micro molds) | X | X | X | X | |

| Spring Loaded or Mechanically Operated KO System | X | X | X | X | X |

| Pre-Hardened Cavity & Core Inserts | X | X | |||

| Aluminum Cavity & Core Inserts or Aluminum Mold | X |

Ready to get started?

If you have any questions about our services or processes please contact T&R Tooling at any time.

We are ready to assist you with any questions or concerns you may have and welcome every opportunity to help you with your needs.

Call or email T&R Tooling using the information provided or use our easy to use forms to contact us anytime.

Telephone: (940) 726-6020

Email: tr@trtooling.com

Plastic Injection Molding Texas

T&R Tooling offers plastic injection molding in Texas from 101 to 528 ton (5 to 65 ounce shot capacity) with core pull and robotic interfaces. Through a close alliance with our affiliates we have access to presses with capacities up to 1000 tons.

Our plastic injection molding shop near you in Texas is fully equipped to handle all fixturing and secondary operations should this be a requirement for your parts.

Assembly & Packaging

T&R Tooling’s expert custom packaging and manual assembly services. We offer bagging, shrink wrapping, boxing, and more, with a focus on quality and timely delivery. Our certified processes ensure the highest standards for your products.

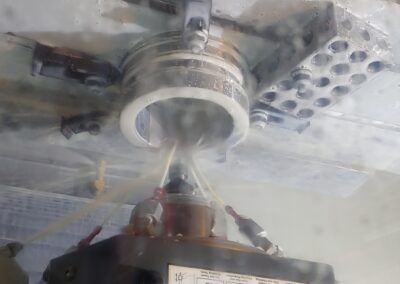

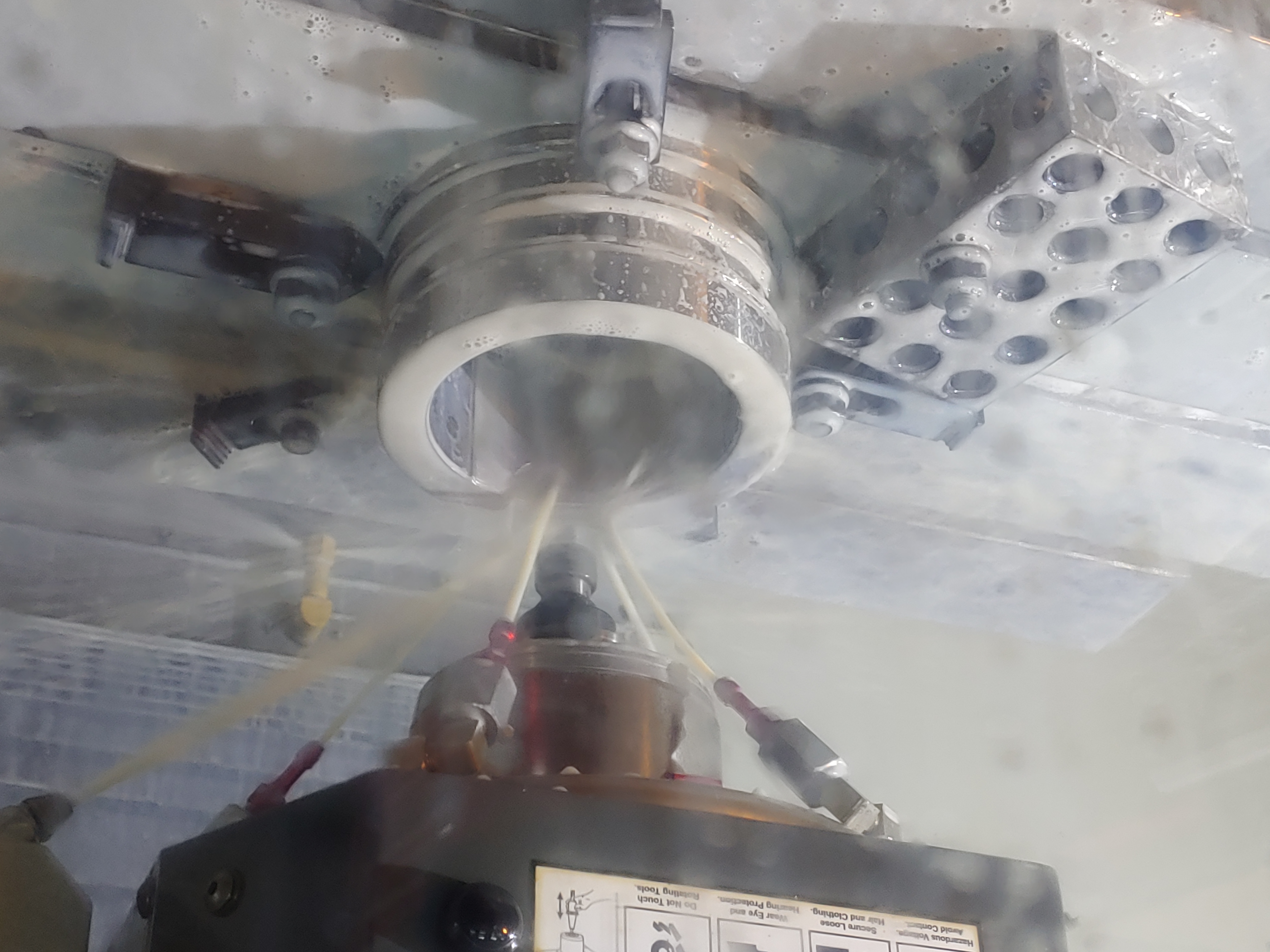

CNC Precision Machining

Our highly skilled injection mold building machinist team is ready to help you with you current or upcoming project. We excel at customer satisfaction. The T&R Tooling staff go the extra mile when it counts whether we are repairing a existing mold or constructing a new one for you. We would love to work with you on your next project.